Florida Man Reviews

Propeller Sizing in 3 Easy Steps

Propeller Sizing in 3 Easy Steps

Airboating Magazine recently caught up with Patti from Whirl Wind Propellers and asked a simple question that we often see from our readers; ‘What prop should I choose that will make the most thrust for my airboat’?

This is what Patti had to say; “Well that is a great question we that we get asked all the time. We have to get into the science a little to best understand what goes into sizing a propeller, so here goes. To get the most thrust from any given propeller and engine combination, the engine must develop the most Horsepower (HP) possible – right! The prop just simply converts this HP into pounds of Thrust.

Patti Rust, Whirlwind Airboat Propellers

Step 1: Horsepower. Sometimes people get hung up on engine Torque vs HP, and are not sure which is most important. In truth, HP is simply a mathematical calculation of Torque and RPM – so HP is Torque with RPM. Without RPM, Torque is meaningless. The formula for HP is simply (Torque x RPM)/5252. Horsepower can be explained as the amount of work done in a given amount of time. Since the engine’s Torque curve doesn’t change linearly as the RPM changes, higher RPM means there’s more work being done every minute even if Torque is flat or decreasing. If you’ve ever looked at an engine dyno sheet, you’ll notice that the HP curve and the Torque curve always cross at 5200 RPM – this is because HP is mathematically calculated from Torque. So, Step 1 – determine max available Horsepower from the engine.

Step 2: RPM. RPM can be divided into 2 categories: Direct-Drive and Reduction-Drive. For direct-drive applications, the maximum engine RPM and maximum propeller RPM will be the same. For direct-drive aircraft engines, these were designed to develop peak HP at 3000 or less RPM with the RPM limitations of propellers in mind. For automotive engines, the choice to use them as a direct-drive application means the HP will be limited to what is developed at 3000 RPM – typically this number is half of the peak HP specified for the engine.

Because automotive engines were never designed to drive a propeller, the peak HP is typically developed at a far higher RPM than any propeller can efficiently (or safely) turn. For this reason, reduction units are used to allow the propeller to turn at an efficient RPM while allowing the engine to develop peak, or close to peak HP. For reduction-drive applications (typically automotive engines and some aircraft engines), the target max engine RPM of the engine should be identified before selecting the reduction ratio. For aircraft engines using a reduction, this is pretty straight-forward. For automotive engines, this is a subject that must take into consideration the “reasonable” maximum engine operating RPM. Reasonable means that even though the engine might make peak HP at 6000 or higher RPM, that may not be practical for several reasons including engine longevity. I suggest big-block engines target in the neighborhood of 5000 RPM (+/-) and the newer small-block LS type engines might target 5200 to 5600 RPM for getting most of the available HP. Ultimately, this is your choice based on your engine and your personal comfort level.

Selection of the reduction ratio is the next step in RPM, once the max engine RPM has been identified. For example, most big-block engines that will only turn 5000 RPM, some of the best all-around ratios fall in the range of 2-to-1 or the popular 2.3-to-1 variations. This means the propeller RPM will be 2500 RPM or 2170 RPM respectively. For engines that plan to turn higher than 5000 RPM, the better ratios are 2.3 or higher (2.5 or 2.68). There is much deeper discussion to be had regarding ratio selection that I wills save for another article. In general, the higher the ratio, the lower the maximum propeller RPM and this will bring in to consideration another factor of dynamic pressure and propeller efficiency that requires more blade area than a higher RPM would require for the same HP output.

Note on the Importance of Max Propeller RPM Limit: When a propeller is turning at full RPM, the centrifugal forces are trying to pull the blades out of the hub. These centrifugal forces acting on the blades increase by a squared factor (non-linear) with RPM. Think of the force of a large pick-up truck swinging of the end. Exceeding the max propeller RPM by 10% is serious and requires the propeller to be inspected. Exceeding the max propeller RPM by 20% could be catastrophic to the propeller structure. Propeller overspeed is serious and can lead to catastrophic failure, injury, or death.

Step 3: Propeller Size. Once the max HP and max RPM for the propeller have been identified, the propeller size can be selected. Propellers can be sized using 3 primary variables: Blade Length, Blade Width, and Number of Blades.

For direct-drive applications, the most common diameter is 72” or less – with the occasional 74” option. This size range is due to the higher 3000 RPM operating limit of direct-drive engines. For direct-drive applications, we offer the CarbonMax™ standard (11” wide) and Narrow (10” wide) in diameters from 66” up to 74”.

For reduction-drive applications, the most common diameter is 78” or larger. We offer a range of blade sizes to work with to accommodate up to 2700 propeller RPM. We offer the 12” wide CarbonMax 2.0 in diameters from 76” to 82” that are best for most 2-1 and some 2.3 or higher reduction ratios. We offer the 13” wide CarbonMax™ EX and the 15” CarbonMax™ SW in diameters from 77” to 84” for 2.3 and higher reduction ratios. The larger the diameter and wider the blade, the lower the maximum RPM – these longer, wider blades were designed to compensate for those larger reduction ratios to boost efficiency, but also happen to be quieter due to the slower turning propeller RPM.

If these 3 Steps in Propeller Sizing have been identified correctly, the propeller selected will ensure you get the absolute maximum amount of Thrust available at your target maximum RPM. We have designed each propeller blade style to allow a custom sizing option for a range of HP and operating RPMs. If your propeller is sized right, your blade angles will end up in the correct range once you set them for your target RPM, and you will know that you are making the most lbs of Thrust per HP possible. To take out the guess work, we have designed our CarbonMax™ propeller systems to be very user friendly with the pitch setting range already engraved in the QuickChange™ hubs. If you do not end up pitched in the correct range, then you know you need to change your propeller selection.

So now that we’ve covered a little, or perhaps a lot of the science, hopefully this has been beneficial to understand some of the basics of propeller sizing. We have designed the wide-blade CarbonMax™ series to be the most advanced composite adjustable propeller system while also being user friendly. Our CarbonMax™ blades feature an electro-formed Nickel leading edge shield so you get a superior damage-resistant prop and a longer service life which is important for the harsh conditions that airboats operate in.

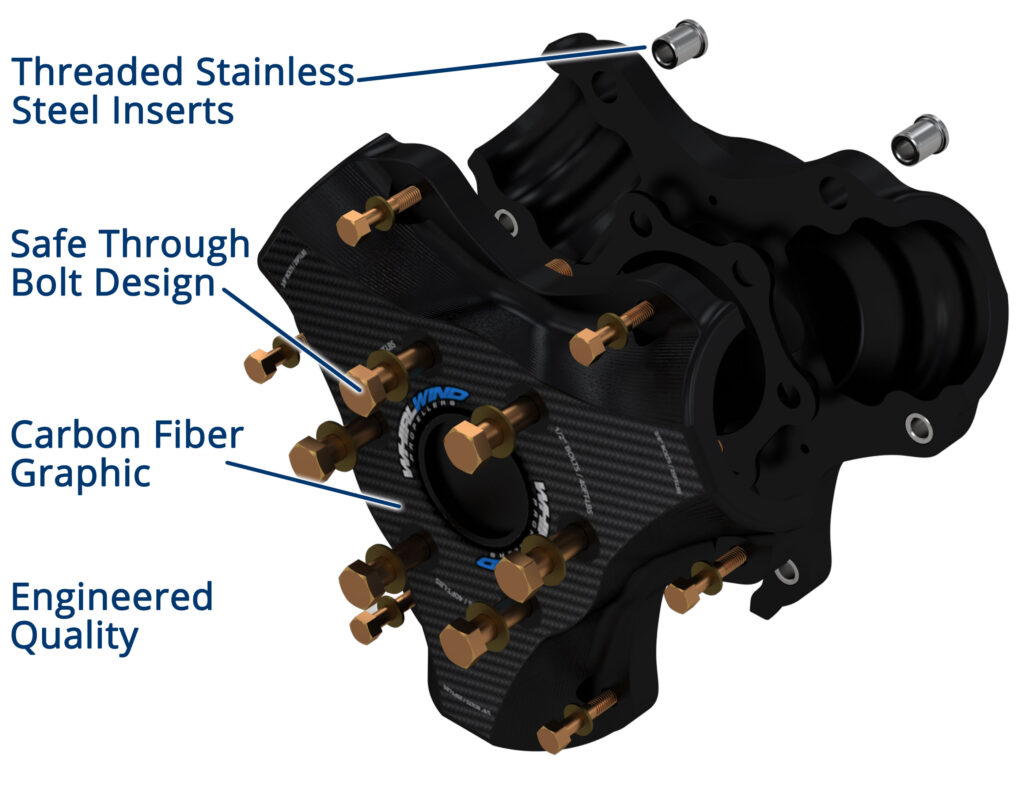

Our QuickChange™ Hub was developed over 20 years ago with a through-bolt design to give you the highest level of safety and strength possible. The QuickChange™ hub has an integral blade pitch guide right on the hub that makes it a breeze to set-up.

Whatever your airboat mission (work, pleasure, hunting or otherwise), we can guarantee that we have the right propeller for your airboat.

FB 25off

Hartline Performance 8B-Razor

Carbon Max Super Wide Testimonial

Hi Whirlwind

I got my new motor and prop all set up! And boy does she RUN now! The set up is great! Thank you for the time you took to talk with me since 2019 and the multiple quotes made until I made up my mind on what set up to go with.

Please see attached pic of boat with new motor and prop as well as a couple other pix of the infamous 4… “POC Wrecking crew”.

Thank you!

Jose

Port O’Conner, TX

Engine: Chevy Big Block (650 hp)

Propeller: 4-Blade CarbonMax™ SuperWide 78″

Airboating in the Snow

Excalibur 5-Blade Testimonial

“Patti

I got my new 5-blade Excalibur prop on (p/v 540 engine) and went for a short ride on Saturday. I was totally overwhelmed by the performance and the throttle response was off the charts! It gave my boat a totally different sound too, and now I can hear the engine so much better. Now the boat will jump out of the water on takeoff, and comes off the dry really well .

My boat is a 14’ Diamondback with a straight valve O540 . This prop is set at 6-deg, and runs 2800 on the trailer WOT.

This what I was looking for! Thank you!”

Mike G.

Ft Myers, FL

Engine: Lycoming Straight Valve O-540

Propeller: Excalibur 5-Blade 72″

Carbon Max Narrow 2-Blade

“Hi, Patti

I finally got the new prop on the boat and got to test it out this weekend. All I can say is WOW!!!!

All performance increases aside, the sound of the prop is so much better. It finally sounds like a real airboat and not an angry weed-eater like it did with the [Brand X]. If the sound was the only advantage over the [Brand X], I’d still be happy.

With the old prop, my boat wouldn’t run dry at all, the boat would just stop as soon it left the water. Now with the new prop, the first time I got to some dry ground I floored it and the boat just took off accelerating like it NEVER would before. I can start and stop on dry ground with ease.

I’m very pleased all around with how my boat is performing with the new prop. Thanks again for all of the help.”

Justin H.

Jacksonville, FL

Engine: Aircraft Lycoming O-320

Propeller: Carbon Max Narrow 68″ 2-Blade

Merchandise Slider

Props and Hulls Slider

Razor X

Newly delivered Panther 18×8 Lightning Airboat powered by a GM 550HP LSA engine and a 2.68 gear-to-gear counter-rotating 80” diameter Razor X propeller. This new 2016 boat and propeller is going into service for Spirit of the Swamp Airboat Rides in Kissimmee, Florida.

Panther Airboats

Propeller: Razor X 80” Counter-Rotator

Engine: GM 500 HP LSA

Reduction: 2.68 Panther Gear-to-Gear

SW Propeller Slider

Whisper Tip

“Hi, just wanted to let you know my prop came in and I absolutely love it! It was so easy to install and about 10 times easier to set the pitch then my Water Walkers. I have it set on A-15 to turn 5200 on the trailer – and man it does great on the ground. Thank you!”

Bronson C.

Breaux Bridge, LA

Engine: 400 SB, 350hp

Reduction: 2:1 Century Belt

Propeller: 2-blade Whisper Tip 2.0 (78” diameter, 12” wide)

Pitch: A-15 / Full Power RPM: 5200

Dear WhirlWind, thank you for the excellent customer service. Your team went above and beyond the call of duty to get our propeller to us overnight, even with shipping delays beyond your control. Many thanks for getting us a top quality propeller in time for getting out on the lake and filling some gator tags. The Whisper Tip 2.0 blades worked flawlessly.

Dan A.

Sarasota, FL

Engine: GO-480 (geared, non-super charged)

Propeller: 3-blade Whisper Tip 2.0 in 78” diameter

Invalid Displayed Gallery

Hi WhirlWind,

Thank you for the great propeller sizing recommendation. I am thrilled with the results.

A. Campbell

Prop Pitch setting: C-12.5, WOT 4000 RPM, 2200 RPM cruise

Propeller: A3 – Whisper Tip 2.0 (12” wide blade) in 78” diameter

Reduction: Gear Box – Rotator – 1.53 to 1

Engine: Cadillac 500 (640 ft-lbs @4000 RPMs)

Josh P.

Cocoa, FL

Engine: 383 Stroker

Reduction: 2:1 KWay

Propeller: AB300 Whisper Tip 2.0 (12” wide, 78” diameter)

Dear WhirlWind, Just and update for you since I last talked to you about options for my 520 gitsu powered airboat. I have tried several different types and brands of props, and I put on the 74” 2-blade Whisper Tip wide blade and it is a great prop! I picked up a tremendous amount of push as well as top end, just wanted to let you know I think you have a great product. I used to be a hard core [brand X] guy but this prop has changed my mind.

Bobby B.

I started the prop out at your suggested 18 degrees, it wound out at 2900 very quickly. WOW, THEN DOUBLE WOW WOW. YOUR SUPER SNAPPER PROP MADE AN IMPRESSION ON ME I WILL NEVER FORGET. 2900 RPM the boat literally leaps on plain. And cruising at 1800 RPM tp 2900 RPM is like I opened Nitrous, That was just testing my settings. I don’t usually drive like that, I can cruise at around 21 to 2200 RPM and not have oil and cylinder heads heating up much. I have aircraft gages for them, and am always watching my temps. I couldn’t cruise with the warp drive at those 2 RPM’s without having to back down to let the 2 temps cool down. I think I am now getting more air pulled over the engine cylinder heads, and that is keeping things cool. Response and handling is totally different now everything is quicker. I am VERY PLEASED AND IMPRESSED. YOU HAVE A GREAT PROP THAT IS FOR SURE. FROM NOW ON WHEN ANYONE ASKS ME WHAT PROP TO BUY, MY RESPONSE WILL BE TRY WHIRLWIND, GIVE THEM A CALL BEFORE YOU CONSIDER ANYONE ELSE. YOU NOT ONLY SOLD ME THE PROP, YOU SOLD ME ON YOUR QUALITY AND CRAFTSMANSHIP. I ALREADY E-MAILED FARON (at American Airboats) MY PLEASURE IN ORDERING AND SUGGESTING YOUR PROP. HE SAID I WOULD BE HAPPY WITH IT, THAT WAS A MILD UNDERSTATEMENT, TO SAY THE LEAST. ONE VERY SATISFIED CUSTOMER.

Morrow D.

I would like to start by saying “Thanks again” for all the help last year in selecting a propeller for my particular application. The engine assembly is a TSIO-520-E. Since these photos were taken, I have installed a new Turbonetics turbocharger. With slight engine work and 18psi of boost, the engine dyno’ed at almost 375hp. (300hp stock) At our elevation of4500 feet, the AB-300, and at 2850rpm the boat clips along at over 72mph. I have to give most the credit to the propeller and you folks at Whirl Wind. Everyone that comes in contact with boat is quite impressed with prop and all other workings!

Jason O.

Patti, Thanks so much for helping me with the direct drive blade upgrade. The Whisper Tip Blades are perfect, and the boat performs absolutely amazing! I will absolutely tell everyone in need of Blades to contact Whirl Wind Propellers.

Bob F.

Propeller : AB200 72″ Whisper Tip

Engine : Direct Drive Chevy

Thanks for your help with my new prop. It arrived on time in good condition and has improved the performance of my airboat by probably 30% and also reduced noise levels by about the same

Very Happy!

Marty W.

Current Prop : 78″ Whisper Tip

Previous Prop: Wood Sensenich 78 x 56

Engine: Small Block Chevy 350 w/ 2;1 Belt Reduction

Here are a few pictures of my 2006 15′ Nighthawk with new Blueprint 396, Rotator 2.68 and Whirlwind EX 3 blade propeller.thanks for the great service!

John F.

Current Prop : AB200 78″ Whisper Tip 2.0

Previous Prop: Wood Sensenich 78 x 56

Engine: Small Block Chevy 350 w/ 2;1 Belt Reduction

Excalibur

New Trend – 5-blade 72” Excalibur on 6-Cyl Aircraft Engines

Lower Cruise RPM, Better Fuel Economy, and Runs the Hill better than your buddies… No Compromise.

Pictured: Special Red Armor Coat on 6-blade 72” Excalibur

-J. Nash (Cocoa, FL)

This prop setup really blew me away across the board any and every aspect of performance. Just wanted to say thanks and great job probably best aircraft prop on the market.

Dan B.

Engine: Continental 520

Propeller: Excalibur 72″ 4-blade

I went for my first test ride today with the Excalibur, and I was very impressed. I bought the 66″ 3-blade for my 12×6’8 Thurman with an 0-320 and the verdict is, this is a great combo. Previously I ran a 66×34 woody and a 66″ 5-blade Warp Drive. I felt like the Excalibur improved the low-end-push and the mid-range, and the top speed between the Warp and Excalibur about the same (which is great!). The noise was much quieter with the Excalibur too.

The biggest gain I noticed was in the mid-range. With the Excalibur I was riding a ‘fast cruise’ at about 1,900-2,000 RPM, whereas the ‘fast cruise’ with my warp was around 2,100-2,200 RPM. Cruise RPM with my woody was even higher than the warp. As far as low-end-push goes, the Excalibur got me up on plane with just a quick stab of the throttle. It runs smooth and the snap is definitely there too. Overall I’m very happy with it. The Excalibur does everything very well. It’s the best prop I’ve ever put on my boat.

Eric J.

Engine: Lycoming O-320

Propeller: Excalibur 66″ 3-blade

So far so good. Set it at 8 degrees and turns 3100 . Pulled off the hill easier than the 2 blade whisper tip. Cruise rpm was 150 less with the Excalibur. I’m impressed so far. Only got a 20 min ride in. A lot of personal issues over thanksgiving. I will be riding again sunday and will try it at 2800 and maybe 3200. I will update you. I think I like this prop a lot. Thanks.

Kerry

Engine: Direct Drive Cadillac

Propeller: Excalibur 72″ 4-blade

I have been airboating since the 1970′s and have run Sensenich propellers on strictly nothing but aircraft motors, from 4-cylinder to 7-cylinder radial engines. Then I changed to Water Walker and have run Water Walker until now.

I got the 4-blade Excalibur from you a few weeks ago, and this prop is it! Bad Ass! Low-end push is excellent, and it has the pep. Everything you need, low, medium, high. Pushing a 15 ft River Master, 520 Continental fuel injected aircraft motor, average RPM with this prop is in the 2,800 RPM range. Plenty of power. Overall nothing to compares to the Excalibur, I highly recommend it.

C. Bell & Family

Engine: 520 Continental

Propeller: Excalibur 72″ 4-blade

Stump Puller

Thank you for both the propellers you sent me – both the SD & SP blades work great! I am very very happy with your props and my friends all like them too! I know I’ll be calling with more orders, so keep up the good work!

Al M.

I have been running your Whirl Wind AB400 propeller now for several months on my airboat. The 4 blade 82″ Stump Puller on a Lycoming GSO540 upstack. I must say that I have tried others in the mean time, and this propeller is simply the best hands down. It is quieter for starters. Not near as much vibration as we all know that some other props have.

But the main thing is the performance that it offers. Much snappier!! Lets you feel the G forces when accelerating!! Tons of push!! Makes hill climbing a snap.

Yes, I have tried all the others. Since I built this boat myself I wanted to find the best performing propeller on the market and without a doubt the Whirl Wind SP prop has been the best performing prop that I have found in all aspects.

Thank you so much for an awesome product!!!”

Tyler C.

Dear Patti, Congratulations!! What great products Whirl Wind Propellers offer! The Stump Puller is the best, you all should be proud of your developments. We have a new power plant, the BEST propeller and an enthusiastic support, what a team. Thank you so much for you and your teams support.

Harold B.

AB3 – Angle Pitch – Prop Lock

Leaders in Performance Technology

A3 Hub Slider

Airboat Pictures

FS Slide

Full Scale Forward Swept (FS) Propeller Blade Test

WhirlWind Propellers had developed a full scale forward swept (FS) propeller blade for proof of concept testing. This is the first full scale forward swept (FS) propeller blade to be manufactured and tested (that we are aware of). The FS Propeller is currently in testing phase and we will share the results. Testing will focus on noise reduction and efficiency increases.

For decades the theoretical benefits of forward swept propeller blade designs have been discussed in the aerospace engineering community. Testing of wind tunnel models and CFD models have shown potential performance improvements and noise reduction for the forward swept propeller blade design. Aerodynamic tip losses plague propeller efficiency and performance, and the forward swept design attempts to address those losses. There have been several attempts to address tip losses using other propeller blade design modifications, such as winglets and fences, but these types of modifications have actually resulted in more drag on the propeller blade and loss in performance.

Racing Slider

Razor X slider

Floral City

Country Music Super Star

Smart Kid

Stan Floyd of American Airboats putting the AirRanger through its paces in Oklahoma with a young passenger that is not bothered a bit by the boat or the giant tree the boat is climbing up and over. Stan says the AirRanger is equipped with a three blade 79 Whisper Tip and custom 600 hp small block w/ a 2.33 belt reduction – the boat is amazingly quiet and extremely powerful… it goes anywhere.”

Roger Walter’s Race Winning Airboat

Kline’s Custom Airboats

Dave Simpson’s EcoBoost 2

Dave Simpson built a new boat with the EcoTech turbo engine. 280 hp @ 5300 w/2.3 gear, He pulled tested 1180 lbs. of thrust.

Engine: EcoTech turbo

Reduction: 2.3

Propeller: AB300 3-Blade