“Propeller is great! We gained 20% true air speed (205KM/H to 245km/H) and saved 9 kg compared to our ********* 72”. Many thanks to all the whirlwind team, it creates emulation around the aircraft today! Few others owners are questioning us and asking for your contact details!

Keep in touch,

Chris”

Aircraft: Robin Dr. 250

Engine: Lycoming O-320

Propeller: GA-200L 72″

hypersonic space propeller

STOL Rotax Propeller Testimonial

Want to thank everyone at Whirl Wind to include the technical folks for Switching out the Warp Drive for the Whirl Wind STOL RW75 has made a dramatic difference in climb/cruise and noticeably quieter for our 912ULS powered Aeroprakt A-22 Valor floatplane on M1400 Clamar floats. It will be great for STOL/Drag racing.

Much appreciated,

Robert

Airplane: Aeroprakt A-22 Valor Floatplane

Engine: Rotax 912

GA-RZ3B (3-blade) for Viking 115 Engine

EFFICIENT – QUIET – LIGHT WEIGHT

WhirlWind’s GA Series propellers (ASTM certified) are designed for LSA type aircraft. Optimized planform shape and proprietary airfoils make this propeller efficient and very quiet in operation. The carbon fiber construction of the GA-RZ blades with X-Core™ composite ensures a safe, strong propeller with low inertia as Viking 115 requires. The Nickel leading edge provides superior abrasion protection and the blade’s high gloss natural carbon fiber finish will satisfy the most discriminating owner.

WhirlWind’s GA blades are constructed from aerospace thermo-set composite materials, and are equipped with a full length electro-formed nickel leading edge for unparalleled durability and precise fit. These blades are light and durable, and are suitable for flying in rain and from unimproved airstrips. WhirlWind’s GA hubs are machined from aerospace grade billet aluminum.

Specifications for GA-RZ3B

|

|

Spinners

Composite Spinner

The optional spinner for the GA-RZ3B-70 propeller is an all composite constructed spinner assembly which includes the spinner dome and rear bulkhead. The spinner kits ship ready for paint with all nut plates installed, no trimming required.

Sizes: 9.75″ or 11.3″

Installation

Use GA-RW3B Instructions for GA-RZ3B

Propeller for Jabiru 3300 Engines

The WhirlWind GA propeller series are ground pitch adjustable aircraft propellers featuring advanced aerodynamic and composite design. The high gloss urethane surface shows off the quality craftsmanship and attention to detail.

The blade design is optimized for maximum efficiency and minimum noise. The blade structure is manufactured from theromoset epoxy/graphite composite matrix. This advanced composite structure ensures high strength and blade accuracy in all flight environments. Only WhirlWind propellers come standard with electroformed Nickel leading edge shields for superior fit and abrasion protection. The hub is CNC machined from aerospace aluminum and is dimensionally certified.

Specifications for GA-J2B

|

|

Spinners

Composite Spinner

WhirlWind offers composite carbon fiber spinners that are already trimmed and fitted and ready to fly.

Construction: Composite

Sizes: 9″, 9.75″ or 11.3″

Installation

Engineering

1) Performance, Innovation, Efficiency

|

| The aerodynamics, pressure/velocity profiles, and three dimensional flow patterns through an aircraft propeller are an order of magnitude more complex than the airflow acting on an equivalent wing. To optimize propeller thrust and maximize achieved aircraft performance, propeller design must balance numerous factors including blade area, aspect ratio, and velocity profile. As such, WhirlWind Propellers employs the most technologically advanced computer flow modeling tools, and incorporates custom designed proprietary airfoil sections from root to tip. Airfoil transitions and blended sections take advantage of the latest understanding and advances in aero-science. Better optimized blade shapes, taper ratios, and thinner, more aggressively tapered tips have been developed by WhirlWind to minimize the induced drag losses that reduce effective engine output and delivered thrust.To ensure that higher performance is actually achieved in real-world conditions, WhirlWind includes the effects of aircraft size, shape, speed range, and mission profile in our performance calculations. This data is then incorporated into the final optimized propeller design. For a given diameter, high speed aircraft will see an increase in cruise performance from less blade area. STOL / utility type aircraft will benefit from greater thrust on takeoff and climb with slightly larger area. Blade twist distribution must be matched to the subject aircraft’s speed, engine RPM, and the size and shape of the cowling, so that the discrepancies between theoretical and actual pressures, velocities and flow behaviors are kept to a minimum.Without such a thorough, scientific approach at the design stage, measurable losses in performance will be “built in” over the life of the propeller. |

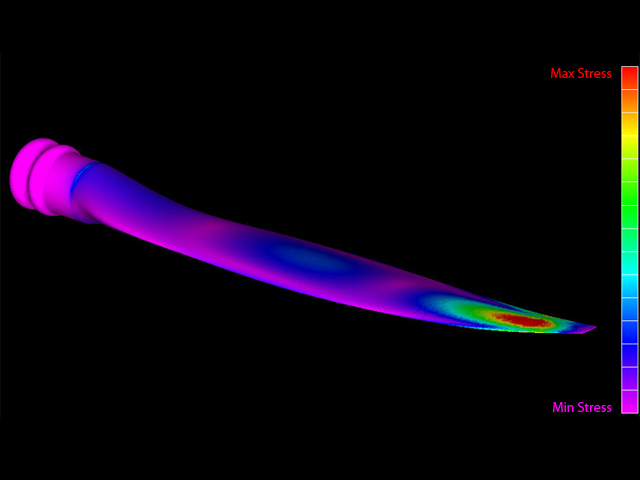

2) Structural Design and Testing

|

| There are several forces acting upon a propeller in flight, including centrifugal, bending, torsional, and dynamic. Torsional loads, lift loads (thrust), and dynamic loads can combine at certain speed and RPM ranges to create potentially dangerous resonance conditions. WhirlWind Propellers uses an advanced proprietary load simulation program to analyze and predict the forces that create these dynamic vibration and resonance conditions. Based on this data, we are able to optimize the composite layup schedule for each blade design, to deliver the correct balance of strength and stiffness versus flexibility. Propeller structures must have flexural properties to allow limited (and predictable) amounts of movement without approaching a “yield” failure of the composite matrix… but they must also retain enough stiffness to prevent the onset of dynamic resonance or instability.After the initial analysis, WhirlWind uses the latest and most advanced test equipment to verify and physically test each propeller design. First, a ground-based Vibration Survey is used to predict the flight conditions where resonance could occur. Strain gauges are then installed on the propeller blades, and the propeller is flight tested though the entire operational design range plus a safety factor. The strain gauge data validates our engineering process in real-world conditions. Thanks to extensive design and engineering capabilities, backed up by real-world flight testing, WhirlWind Propellers have no “Service Life” limits or restricted operating RPM ranges. |

3) Excellence in Manufacturing

|

| WhirlWind Propellers is proud to be a vertically integrated technology company. We embrace industry-leading best practices in each step of the manufacturing process, and use only the highest quality aerospace materials in the construction and assembly of each propeller. The latest CAD/CAM manufacturing tools ensure that every propeller will meet the original design specifications. WhirlWind uses CNC machined aircraft aluminum propeller hubs to maintain precision tolerances. Computer cut pre-preg composite materials guarantee accuracy and consistency in blade laminate structure. Electro-formed Nickel leading edge protection is used to provide unmatched durability and abrasion resistance. WhirlWind also uses all composite core materials; there is no wood to absorb moisture, crack, or change shape over time. Your investment in performance and safety is in the right hands with WhirlWind Propellers. |

High Stress Region |

Propeller Blade Mode Shape |

Vibration Survey |

Propeller Theory – 1944

Propeller Theory – 1944

Curtiss-Wright Corporation

Download PDF: “Propeller Theory – 1944, Curtiss-Wright Corporation”

Download PDF: “Propeller Theory – 1944, Curtiss-Wright Corporation”